×

- Live Chat

- 1-888-505-1906

My Garage

My Account

Cart

Genuine Acura Integra Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

32 Drive Belts found

Acura Integra Power Steering Pump Belt

Part Number: 56992-P72-004$24.13 MSRP: $33.65You Save: $9.52 (29%)Acura Integra Alternator Belt

Part Number: 31110-P73-508$36.78 MSRP: $51.30You Save: $14.52 (29%)Ships in 1-3 Business DaysAcura Integra Alternator Belt

Part Number: 31110-PJ7-033$9.62 MSRP: $19.38You Save: $9.76 (51%)Ships in 1-2 Business DaysAcura Integra Compressor Belt

Part Number: 38920-PR4-A04$13.94 MSRP: $22.47You Save: $8.53 (38%)Ships in 1-2 Business DaysAcura Integra Alternator Belt (Mitsuboshi)

Part Number: 31110-P2T-004$18.92 MSRP: $26.39You Save: $7.47 (29%)Ships in 1-3 Business DaysAcura Integra Alternator Belt

Part Number: 38920-P30-004$12.03 MSRP: $19.93You Save: $7.90 (40%)Ships in 1-2 Business DaysAcura Integra Compressor Belt (Bando)

Part Number: 38920-PR4-A01$13.83 MSRP: $19.76You Save: $5.93 (31%)Acura Integra Alternator Belt (Bando)

Part Number: 31110-PR4-003$13.99 MSRP: $19.98You Save: $5.99 (30%)Acura Integra Powerdrive Motors Replacement Belt

Part Number: 31110-PR4-004$13.99 MSRP: $19.98You Save: $5.99 (30%)Acura Integra Alternator Belt (Bando)

Part Number: 31110-PR4-A05$13.99 MSRP: $19.98You Save: $5.99 (30%)Acura Integra Power Steering Belt

Part Number: 56992-P72-505$24.13 MSRP: $33.65You Save: $9.52 (29%)Ships in 1-3 Business DaysAcura Integra Belt, Alternator

Part Number: 31110-5AG-Z01$52.15 MSRP: $72.73You Save: $20.58 (29%)Ships in 1-3 Business DaysAcura Integra Belt, Alternator

Part Number: 31110-66V-A01$33.64 MSRP: $46.92You Save: $13.28 (29%)Ships in 1-2 Business DaysAcura Integra Alternator Belt (Bando)

Part Number: 31110-PR4-A03$12.60 MSRP: $17.57You Save: $4.97 (29%)Ships in 1-3 Business DaysAcura Integra Alternator Belt (Mitsuboshi)

Part Number: 31110-PR4-A04$12.60 MSRP: $17.57You Save: $4.97 (29%)Ships in 1-3 Business DaysAcura Integra Compressor Belt (Made In U.S.A.) (Mitsuboshi)

Part Number: 38920-PR4-A12$16.11 MSRP: $22.47You Save: $6.36 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 32 Results

Acura Integra Drive Belt

We provide a broad range of OEM Acura Integra Drive Belt at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Drive Belt Parts Questions & Experts Answers

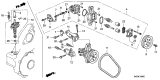

- Q: What is the purpose and importance of the drivebelts on Acura Integra?A: The front of the engine has a set of V-belts that are responsible for its functioning and those of the vehicle. Eventually, wear and tear will cause them to fail because of their operational characteristics as well as the type of material used in making them, hence, they have to be inspected periodically and adjusted to avoid serious damage to the engine. The number of belts required is determined by what accessories are being used. These include turning the alternator, power steering pump and air-conditioners compressor. It is therefore possible for a single belt to drive more than one such entities depending on how pulleys are arranged. To check these belts, open your car's bonnet with an engine stopped. Inspect for cracks, plies splitting apart; fraying and shiny appearance. Each side should be looked at. Belt tension can be checked by pressing down halfway between the pulleys on each belt. The belt-driven accessory which helps in adjusting tension if necessary is moved on top moving bracket as shown below if it needs adjustment for tensioning purposes while another type uses an adjustable idler pulley mounted between driven accessory and crankshaft pulley (e.g., some air conditioning compressors), or moved within its own bracket towards or away from driven accessory (on other air conditioning compressors). If you need more information about these adjustments, consult your manual at nearest automobile firm office or check here Adjusting bolt(s) are loosened which release power steering pump from its bracket so that it can be shifted causing belt slackness when directed away from engine during belt tightening process then pushed back against engine before re-tightening bolts after determining correct alignment position it should maintain based upon manufacturer specifications until fully tightened up again using relevant wrench size many auto shops sell so ask sales person about different models available including discounted rates offered during certain periods At this stage we may need to measure how tight our drivebelt should be; so far I mentioned loosening components then tightening them later on after making sure that they are correctly aligned with each other. Pull it off of the crankshaft pulley and remove it the belt. Furthermore, replacing all belts at once is advisable. Each one should be marked and its corresponding groove noted in order to put on a new belt properly. Before you go buying some new ones, bring along your old versions for comparison purposes either by having someone come over while carrying them or take them there directly to ensure getting right sizes as well as type desired Adjust them as discussed previously.